The global climate crisis demands more than incremental change; it requires a fundamental reimagining of how we produce, consume, and power our world. At the forefront of this seismic shift stand companies transcending mere compliance to become true champions of green technology and holistic sustainability. These organizations are not just deploying clean solutions; they are embedding environmental and social responsibility into their core DNA, redefining supply chains, pioneering disruptive technologies, and proving that profitability and planetary stewardship are not mutually exclusive but intrinsically linked. Their journeys, grounded in verifiable action and measurable impact, illuminate the path toward a genuinely sustainable future. Driven by a potent combination of ethical imperative, investor pressure, consumer demand, and regulatory tailwinds like the EU’s Green Deal and CBAM, these vanguards are demonstrating scalable solutions across diverse sectors, transforming ambition into tangible reality through relentless innovation and unwavering commitment.

In the critical realm of renewable energy generation and transition, Ørsted stands as a paradigm-shifting exemplar. This Danish powerhouse has undergone one of the most radical corporate transformations witnessed, evolving from Danish Oil and Natural Gas (DONG) to a global leader exclusively focused on renewables. Their audacious commitment is reflected in achieving a 94% reduction in scope 1 and 2 emissions since 2006 (validated by the Science Based Targets initiative – SBTi), with a firm target to become carbon-neutral by 2025, encompassing their entire energy generation and operations. Ørsted is not merely building wind farms; they are pioneering biodiversity protection measures like artificial reefs around turbine foundations and investing heavily in Power-to-X technologies, exploring green hydrogen and e-fuels to decarbonize harder-to-abate sectors like shipping and aviation. Their leadership extends beyond their own operations, actively engaging suppliers to reduce emissions across their value chain, understanding that true sustainability demands systemic change. Similarly, NextEra Energy, through its subsidiary NextEra Energy Resources, has become the world’s largest generator of renewable energy from wind and solar, boasting over 34 gigawatts (GW) of installed capacity as of Q1 2024 and a staggering development pipeline exceeding 20 GW. Their strategic investments in battery storage – deploying over 3 GW globally – are crucial for grid stability as intermittent renewables proliferate, showcasing an integrated approach to the clean energy transition. Their ambitious “Real Zero” goal targets eliminating all scope 1 and 2 emissions by 2045 without relying on offsets, a testament to their commitment to genuine decarbonization, backed by massive capital expenditure plans exceeding $85 billion for 2023-2026 focused on renewables and grid modernization.

The transportation sector, a major emissions source, is being revolutionized by champions like Tesla, whose impact extends far beyond popularizing electric vehicles. Tesla’s core mission accelerates the shift to sustainable energy, evidenced by deploying over 20 Terawatt-hours (TWh) of cumulative clean energy generation and storage through its solar panels and Powerwall/Powerpack/Megapack batteries as of 2023. Their relentless focus on battery technology – reducing cobalt content, increasing energy density, and driving down costs – has been instrumental in making EVs accessible. While facing scrutiny over its own supply chain, Tesla actively sources responsibly, publishing annual Impact Reports detailing mineral sourcing and recycling efforts, and its Gigafactories increasingly utilize on-site solar and aim for high levels of renewable energy use. Their vertically integrated approach, controlling battery production and software, allows for rapid innovation cycles crucial for scaling sustainable transport. Complementing vehicle electrification is the critical need for sustainable logistics, where Maersk is making bold strides. The global shipping leader has committed to achieving net-zero greenhouse gas emissions by 2040, a decade ahead of the initial IMO industry target. Their tangible action includes ordering 25 dual-fuel vessels capable of running on green methanol, with the first already operational, and securing partnerships to scale green fuel production. Maersk is actively exploring ammonia as another zero-emission fuel pathway and heavily investing in optimizing vessel operations through AI for route and speed optimization, significantly reducing fuel consumption even with conventional fuels while the green fuel infrastructure scales. Their Eco Delivery product, offering customers carbon-neutral transport using sustainable biofuels, demonstrates market-driven solutions, with volumes growing exponentially year-on-year.

The technology hardware sector, grappling with resource intensity and complex global supply chains, finds leadership in companies like Apple. Apple’s ambition is profound: to make every product carbon neutral by 2030, encompassing its entire global supply chain and product lifecycle. This requires monumental effort, and progress is tangible. They have achieved 100% renewable electricity for their global corporate operations since 2018 and are driving their vast manufacturing network – over 300 suppliers as of 2023 – toward the same goal, with commitments covering over 16 gigawatts of renewable energy online. Apple is pioneering material innovation and circularity: the latest Apple Watch models incorporate 100% recycled cobalt in batteries and 100% recycled gold in plating and wire, the MacBook Air with M3 features 50% recycled plastic and 100% recycled aluminum in the enclosure, and they are utilizing recycled rare earth elements across components. Their disassembly robots, like Daisy and Dave, and growing network of Material Recovery Labs aim to close the loop, targeting eliminating mining altogether through advanced recycling and material substitution. Patagonia, while an apparel company, operates with the ethos and impact of a green tech champion, particularly in material science and supply chain ethics. Its self-imposed “Earth tax,” the 1% for the Planet commitment, has donated over $200 million to environmental groups since 1985. Patagonia relentlessly innovates with recycled materials (over 87% of their line used recycled materials in Fall 2023), organically grown cotton (eliminating pesticides since 1996), and regenerative organic certified practices to rebuild soil health. Their radical transparency through the Footprint Chronicles traces materials back to farms and factories, holding themselves and suppliers accountable. Most significantly, founder Yvon Chouinard transferred ownership to a Purpose Trust and non-profit in 2022, ensuring all company profits fund climate and conservation efforts, structurally embedding planetary health above shareholder returns – an unprecedented corporate model prioritizing sustainability as its core fiduciary duty.

The enablers of circularity and resource recovery are equally vital champions. Redwood Materials, founded by former Tesla CTO JB Straubel, tackles the looming challenge of end-of-life batteries head-on. Their mission is to create a closed-loop domestic supply chain for critical battery materials. Their hydrometallurgical process recovers over 95% of the critical metals like lithium, cobalt, nickel, and copper from end-of-life batteries and manufacturing scrap, significantly reducing the need for environmentally damaging virgin mining and enhancing supply chain security. Redwood is rapidly scaling its Nevada operations and expanding into South Carolina, partnering with major automakers (Ford, Volkswagen, Toyota) and battery producers (Panasonic) to secure feedstock and supply recycled materials for new batteries, aiming to produce anode and cathode components with a drastically lower carbon footprint than virgin materials by 2025. In the realm of industrial decarbonization, H2 Green Steel is a pioneering force demonstrating disruptive green tech. Utilizing hydrogen produced via electrolysis powered exclusively by Sweden’s abundant renewable electricity, they are building the world’s first large-scale green steel plant in Boden. This process eliminates the fundamental need for coking coal, the source of ~90% of the steel industry’s CO2 emissions. Their offtake agreements with major manufacturers like BMW, Mercedes-Benz, and Siemens (representing over 7 billion Euros in future revenue by 2030) underscore the market demand for truly green primary steel. Their model offers a blueprint for decarbonizing one of the world’s most carbon-intensive industries, proving the technical and commercial viability of green hydrogen in heavy industrial processes.

These champions, while diverse in their sectors and strategies, share common threads: audacious, science-based targets validated by organizations like SBTi; radical transparency in reporting progress and challenges; deep integration of sustainability into core R&D and business models, not peripheral CSR; pioneering collaboration across value chains to drive systemic change; and a willingness to invest heavily upfront for long-term planetary and economic resilience. They navigate complex challenges – scaling green hydrogen and SAF, ensuring ethical mineral sourcing, perfecting large-scale recycling, managing Scope 3 emissions across sprawling networks – but their progress is demonstrable and accelerating. Their leadership proves that the green tech revolution is not just about generating clean energy but about fundamentally transforming how we build everything, from the molecules upwards, creating a circular, equitable, and truly regenerative economy. They are not merely participants in the sustainability movement; they are its architects, demonstrating through concrete action that a thriving future for business is inextricably linked to a thriving planet. Their continued innovation and scaling efforts represent humanity’s most promising engine for achieving a net-zero, nature-positive world.

India’s aviation sector is soaring—literally. With over 150 million passengers in 2023 and projections to become the world’s third-largest aviation market by 2026, the environmental toll is impossible to ignore. Airports contribute 5% of global aviation emissions, and India’s aviation sector alone emits 20 million tons of CO₂ annually. Yet, amidst this growth, a quiet revolution is unfolding. From Cochin’s solar-powered terminals to Delhi’s wastewater recycling systems, India is pioneering a new model for sustainable aviation infrastructure.

This is the story of how Indian airports are balancing explosive growth with ecological responsibility—and what the world can learn from their experiments.

Cochin International: The World’s First Fully Solar-Powered Airport

In 2015, Cochin International Airport (CIAL) in Kerala made history by becoming the first airport in the world to run entirely on solar power. What began as a 12 MW solar plant has now expanded to 50 MW, generating 200,000 units of electricity daily—enough to power 60,000 homes. On sunny days, the airport feeds surplus energy back into the state grid.

The numbers speak for themselves:

But CIAL didn’t stop at solar. The airport also:

The lesson? A single innovation—solar energy—can catalyze broader sustainability efforts.

Delhi’s IGI Airport: A Megahub Goes Green

Delhi’s Indira Gandhi International (IGI) Airport, handling 70 million passengers annually, faces a unique challenge: scaling sustainability without disrupting operations. Its multi-pronged approach includes:

Energy: From Carbon-Intensive to Net-Zero

Water: Closing the Loop

3. Waste: From Landfill to Circular Economy

The lesson? Even mega-airports can decarbonize—if they treat sustainability as an operational priority, not just PR.

Mumbai’s Chhatrapati Shivaji Maharaj Airport: The Carbon-Neutral Pivot

Mumbai’s airport, constrained by urban sprawl, turned to smart design and tech to reduce emissions by 50% :

Its most innovative move? Vertical gardens along terminal walls—30,000 plants that absorb 1.5 tons of CO₂ annually while reducing indoor temperatures by 3°C.

The lesson? Urban airports can leverage space-efficient green tech to compensate for land limitations.

Noida International Airport (Jewar): The Greenfield Revolution

Slated to open in 2025, Noida International Airport (NIA) is designing sustainability into its DNA:

Its Digital Tower—controlled remotely from 50 km away—eliminates the need for energy-intensive ATC buildings.

The lesson? Greenfield projects can leapfrog legacy systems and set new benchmarks.

The Challenges: Why India’s Green Airport Dream Isn’t Easy

Despite progress, hurdles remain:

Yet, the Airports Authority of India (AAI) is pushing forward:

The Future: What’s Next for Indian Aviation?

As ICAO’s Aviation Environmental Report 2023 notes, India is now a global testbed for scalable green airport solutions.

India’s airport infrastructure is emerging as a global benchmark in combining growth with sustainability. Cochin International Airport leads by example with its pioneering solar energy adoption, becoming the world’s first fully solar-powered airport. Delhi’s Indira Gandhi International Airport has implemented closed-loop water systems and energy-efficient retrofits, demonstrating how existing infrastructure can be optimized for lower emissions. Meanwhile, Noida’s upcoming greenfield airport is embedding sustainable practices from the ground up. These models show that emerging economies can build for expansion while prioritizing renewable energy, water conservation, and green design from the outset.

As Union Aviation Minister Jyotiraditya Scindia declared: “Our airports will be net-zero—not because it’s trendy, but because it’s essential.” For a sector often criticized for its climate impact, India’s green airports are rewriting the rules—one solar panel at a time.

On a typical day, over 100,000 flights crisscross the globe, leaving behind contrails and a staggering carbon footprint. As the world grapples with climate change, this dilemma in the area of aviation as become almost an existential challenge. The industry accounts for 2.5% of global CO₂ emissions, a figure projected to triple by 2050 without intervention. With electric planes still decades away from commercial viability for long-haul flights, and also as international travellers increasingly opt for carbon offsets, Sustainable Aviation Fuel (SAF) has emerged as the most realistic pathway to decarbonize air travel. Made from renewable sources like agricultural waste, algae, and even carbon captured from the air, SAF can reduce aviation’s carbon footprint by up to 80% compared to conventional jet fuel.

India, with its rapidly growing aviation market (projected to become the world’s third-largest by 2026) and vast agricultural resources, stands at a critical juncture. According to a Deloitte report highlighted in The Economic Times, India could produce 8-10 million tonnes of SAF annually by 2040, enough to meet 20% of its projected jet fuel demand. But will the country seize this opportunity, or remain grounded by policy inertia?

Every winter, northern India’s skies turn toxic as farmers burn an estimated 230 million tonnes of agricultural residue, primarily rice straw. This environmental catastrophe could instead become the foundation of India’s SAF industry. Praj Industries, a pioneer in biofuels, has already demonstrated that rice straw and sugarcane bagasse can be converted into drop-in aviation fuel through advanced biochemical processes.

The International Air Transport Association (IATA) sees India’s agricultural byproducts as a game-changer: “With proper collection infrastructure, India could supply enough feedstock not just for domestic needs but for export markets,” says Preeti Jain, IATA’s Assistant Director for India. The numbers support this optimism – every tonne of agricultural waste converted to SAF prevents 3 tonnes of CO₂ emissions compared to conventional jet fuel.

India’s 2.7 million tonnes of used cooking oil (UCO) generated annually presents another promising feedstock stream. Companies like Biofuels Junction are already aggregating UCO from restaurants and food processors for biodiesel production. Scaling this model for SAF could create a circular economy where Mumbai’s samosa oil eventually powers flights from Delhi to Dubai.

Despite its potential, India’s SAF industry remains in the taxiing phase. While the U.S. offers a $1.25/gallon tax credit for SAF producers and the EU mandates 2% blending from 2025, India lacks comparable incentives.

While the Bio-Aviation Turbine Fuel Policy (2021) marked a significant step in acknowledging Sustainable Aviation Fuel (SAF) as part of India’s energy transition, its impact has been limited due to a lack of enforceable regulations and financial mechanisms. The policy’s voluntary blending targets, rather than mandatory quotas, have failed to drive large-scale industry adoption. Unlike the European Union’s ReFuelEU mandate, which enforces a 2% SAF blending requirement from 2025, India’s approach relies on goodwill rather than binding commitments.

Compounding the issue is the absence of financial incentives for SAF producers. In contrast, the U.S. Inflation Reduction Act (IRA) provides a $1.25 per gallon tax credit, dramatically accelerating domestic SAF production. Without similar subsidies or tax breaks, Indian refiners and biofuel companies face prohibitive costs, making SAF three to five times more expensive than conventional jet fuel.

Additionally, India lacks standardized certification systems for alternative feedstocks like agricultural residue and used cooking oil. This regulatory gap creates uncertainty for investors and delays the scaling of new SAF production methods.

The consequences of this policy inertia are stark. An OpenPR market analysis projects that global SAF production will grow at a 40% compound annual growth rate (CAGR) through 2030, driven by aggressive mandates in the U.S. and Europe. Meanwhile, India—despite its vast agricultural waste resources and rapidly expanding aviation sector—risks falling behind in this critical energy transition. Without urgent policy reforms, the country may miss its chance to become a major SAF producer, instead becoming dependent on costly imports to meet future decarbonization targets.

The Indian Companies Betting on SAF

Praj Industries: The Biofuel Vanguard

The Pune-based company’s “Bio-Mobility” platform has already supplied test batches of SAF to Indian airlines. Their upcoming second-generation (2G) ethanol plants can be retrofitted for SAF production once economics improve.

Indian Oil: The Refinery Revolution

India’s largest oil company is converting part of its Panipat refinery to produce 87,000 tonnes/year of SAF from agricultural waste by 2025. As noted in The Economic Times, this pilot could catalyze industry-wide adoption.

Startups: The Disruptors

Three Possible Flight Paths

As India stands at the crossroads of sustainable aviation, its trajectory in the coming decades could follow one of three distinct scenarios, each with profound implications for its economy, environment, and global energy standing.

The most concerning outlook is The Laggard Scenario, where continued policy inertia leaves India dependent on imported SAF to meet international obligations. By 2040, without domestic production incentives, Indian airlines would be forced to purchase SAF at premium prices to comply with stringent EU blending mandates for Europe-bound flights. This import dependence would not only strain airline finances but also represent a missed opportunity to capitalize on India’s vast agricultural resources, keeping the country on the sidelines of the global green fuel revolution.

A more balanced middle ground emerges in The Middle Path Scenario, where measured policy interventions – perhaps a modest blending mandate of 1-2% combined with limited tax incentives – could unlock domestic SAF production of 3-5 million tonnes annually by 2040. While this would primarily serve domestic aviation needs, it would establish crucial infrastructure and know-how for future expansion. This scenario would see India meeting its own decarbonization goals while avoiding the worst aspects of import dependence, though without capturing the full economic potential of its feedstock advantages.

The most ambitious and transformative possibility is The Global Leader Scenario, where bold policy actions position India as the Saudi Arabia of sustainable aviation fuel. With aggressive blending mandates (5%+), robust production incentives, and strategic investments in feedstock supply chains, India could emerge as a major SAF exporter to Asia and Europe. This path wouldn’t just secure India’s energy independence in aviation – it would create an estimated 300,000 rural jobs in agricultural waste collection, slash farm fire pollution by 40%, and generate a staggering $15 billion in annual revenue according to Deloitte estimates. Such an outcome would transform India from an energy importer to a clean fuel powerhouse, while simultaneously addressing critical environmental and rural economic challenges.

The divergence between these scenarios underscores a critical truth: India’s future in sustainable aviation won’t be determined by technological constraints or resource limitations, but by the ambition and urgency of its policy framework in the coming years. The runway is clear – the question is whether India will taxi cautiously or accelerate toward leadership in the global SAF market.

The pieces are in place: abundant feedstock, proven technology, and hungry corporate players. What’s missing is the policy thrust – blending mandates, tax credits, and R&D funding – to get India’s SAF industry airborne.

As global aviation faces mounting pressure to decarbonize, India stands before a rare opportunity: to transform its agricultural waste into green gold, powering not just its own skies but those of the world. The question isn’t technical or economic – it’s political. Will India’s leaders have the vision to fuel this revolution?

Here is the prescription for sustainability… In a world where the pharmaceutical industry plays a pivotal role in safeguarding human health, a new, sobering reality has emerged, that the very industry tasked with healing the world is leaving behind an environmental footprint that could endanger it. From antibiotic residues flowing into rivers to emissions from manufacturing hubs in Asia, the pharmaceutical supply chain is facing growing scrutiny. The conversation is no longer just about efficacy and access; it is increasingly about sustainability.

At the heart of this reckoning is the alarming rise of pharmaceutical pollution. This is an issue spotlighted during a landmark virtual workshop hosted by Health Care Without Harm (HCWH) Europe in September 2024. The discussions revealed a stark truth: the industry’s environmental impact spans continents, with Europe heavily dependent on Active Pharmaceutical Ingredients (APIs) and generics manufactured primarily in India and China. The scale is enormous — 70% of all dispensed medications in Europe are generics, and the environmental cost of their production often lies hidden in distant countries.

Studies have shown that traces of pharmaceutical compounds, from hormones to antibiotics, are found in over 86% of global river samples, creating unintended side effects on ecosystems and accelerating threats like antibiotic resistance (AMR). With an ageing population, rising chronic illnesses, and the cascading impacts of climate change, pharmaceutical use is projected to skyrocket. In Germany alone, demand is expected to surge by up to 67% by 2045.

The challenge is as complex as it is urgent. Antibiotics, for example, once hailed as miracle drugs, are now contributing to a silent crisis. Their residues often leach into the soil and waterways, disrupting delicate microbial ecosystems and fostering resistant strains of bacteria. Recognizing this, the AMR Industry Alliance, established after the 2016 Davos Declaration, is championing responsible effluent management. It developed a Common Antibiotic Manufacturing Framework, now strengthened with an industry-backed certification scheme via the British Standards Institute. This sets stringent limits on antibiotic emissions from manufacturing plants, ensuring discharges remain below predicted no-effect concentrations.

But global adoption remains uneven. While Nordic countries have begun incorporating environmental standards into their procurement policies, others lag behind. Moreover, the World Health Organization (WHO) has stepped in with even stricter guidelines, including mandatory effluent chemical analysis. Yet, alignment between WHO’s approach and the industry’s remains a work in progress.

Sustainable procurement is emerging as a powerful lever for change. In Europe, where public healthcare accounts for a staggering 40% of GDP, greener purchasing can influence the entire supply chain. HCWH Europe is leading the charge, supporting hospitals and procurement bodies with tools like the Sustainable Procurement Index for Health and guidelines for phasing out chemicals of concern. Governments are beginning to recognize that their purchasing power can either perpetuate pollution or become a force for ecological healing.

Legislation, too, must catch up. The United Nations Environment Programme (UNEP) has pointed out that pharmaceutical pollution is still largely unregulated. The European Green Deal could become a turning point, offering a robust framework to address environmental impacts from “cradle to grave” — from production and packaging to use and disposal. Stronger laws, if implemented with nuance, could drive innovation rather than stifle access, ensuring medicines remain both affordable and environmentally responsible.

Still, legal frameworks alone are not enough. A genuine transformation of the pharmaceutical supply chain requires a paradigm shift. That means moving from treatment to prevention — reducing demand for pharmaceuticals through investments in public health, disease prevention, and lifestyle education. Healthier societies need fewer drugs, lowering both environmental and financial burdens.

Collaboration will be critical. Initiatives like the Pharmaceutical Supply Chain Initiative (PSCI) and Sweden’s PLATINEA platform demonstrate how cross-sector dialogue, involving academia, industry, governments, and civil society, can foster trust and co-create effective solutions. From researchers bridging ecotoxicology gaps to anthropologists tackling social equity, a truly sustainable pharmaceutical future must embrace systems thinking.

Transparency and accountability must also evolve. Public reporting on environmental performance should become standard practice for pharmaceutical firms, guided by global standards like the AMR Alliance’s certification scheme and the upcoming Corporate Sustainability Due Diligence Directive (CSDDD). Yet, careful implementation is vital — too much red tape could choke smaller players and disrupt global medicine access.

Ultimately, greening the pharmaceutical supply chain is not just a technical challenge, it is a moral imperative. At stake is not just the integrity of ecosystems or the purity of rivers, but the very health of the communities these medicines are meant to serve. The solutions lie in innovation, legislation, collaboration, and above all, a shared recognition that healthcare must do no harm, not only to people but to the planet we all depend on.

Airports occupy a unique position in the climate crisis. As vital economic engines that connect people and goods globally, they also contribute significantly to environmental degradation. The aviation sector accounts for 2.5% of global CO₂ emissions, with airports themselves responsible for 5% of that footprint—equivalent to the annual emissions of 50 coal-fired power plants. Yet, across the world, a quiet revolution is unfolding. From Singapore’s rainforest-filled terminals to Sweden’s fossil fuel-free hubs, airports are reimagining what it means to be sustainable in an era of climate urgency.

This is the story of how airports worldwide are balancing growth with ecological responsibility—and what their experiments reveal about the future of green travel.

Changi Airport, Singapore: The Jungle in the Terminal

Singapore’s Changi Airport, consistently ranked the world’s best, has redefined sustainability by integrating biodiversity into its architecture. Its Jewel Terminal, opened in 2019, features:

But Changi’s most radical innovation is biophilic design—using nature to enhance efficiency. The rainforest acts as a natural air purifier, reducing the need for mechanical ventilation, while smart glass adjusts transparency to minimize cooling demands.

The lesson? Sustainability doesn’t mean sacrificing luxury—it can enhance it.

Stockholm Arlanda, Sweden: The First Fossil Fuel-Free Airport

In 2020, Stockholm Arlanda Airport became the first major airport to achieve fossil fuel-free ground operations. Its strategy includes:

The results? A 75% drop in CO₂ emissions since 2010, despite a 40% increase in passengers.

The secret? Sweden’s aviation fuel tax, which funds green initiatives, and a collaborative approach with airlines like SAS, which now uses Sustainable Aviation Fuel (SAF) on all flights.

The lesson? Policy incentives + private-sector partnerships = rapid decarbonization.

Costa Rica’s Juan Santamaría Airport: The Carbon-Neutral Pioneer

In 2021, Juan Santamaría Airport became Latin America’s first carbon-neutral airport. How?

Crucially, the airport worked with local farmers to source organic food for lounges, cutting food-miles by 80%.

The lesson? Small airports can lead—by leveraging local ecosystems.

Boston Logan, USA: The Quiet Revolution

Boston Logan, built in 1923, proves old airports can go green too and cut emissions 40%:

Its real-time energy dashboard lets passengers see their carbon impact—a behavioral nudge copied by 15+ global hubs.

The lesson? Retrofits can be as impactful as new builds.

However, there are reasons why green airports aren’t everywhere. Three key barriers slow the global adoption of sustainable airports: prohibitive costs (solar runways triple standard tarmac expenses), inconsistent regulations (only 12% of countries enforce decarbonization), and lagging airline adoption (just 0.1% of flights use SAF). While these challenges persist, ICAO’s binding 2050 net-zero pledge is accelerating change, proving that today’s obstacles may become tomorrow’s standard practices.

Next-gen airports are embracing radical innovations: Oslo pilots liquid hydrogen refueling by 2025, Dubai’s AI-optimized solar grids slash energy waste 20%, and Zurich pioneers blockchain carbon offsets for passengers. These breakthroughs signal aviation’s tech-driven green revolution.

From Singapore’s biophilic terminals to Sweden’s fossil-free runways, these airports prove sustainability and scalability can coexist. The runway to net-zero is clear—the question is who will follow.

It’s 2037. In a recycling facility just outside Kigali, a teenage girl named Amina watches robotic arms gently disassemble discarded solar panels. She’s one of thousands in Africa’s new wave of circular economy engineers—part of a movement that’s rewriting humanity’s relationship with resources. The panels came from an EV station in Germany. Their next life? Battery enclosures in Kenya’s grid-storage farms. Nothing is wasted. Nothing is lost. Every molecule accounted for.

This is not science fiction. This is the new metabolism of the green tech world.

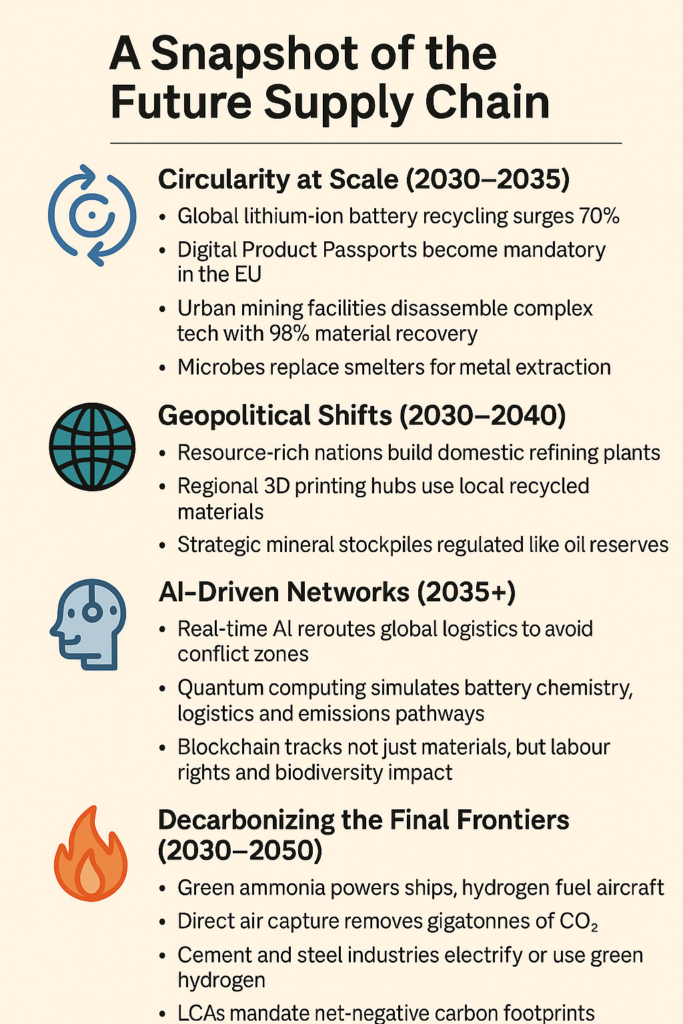

By 2030, the global supply chain isn’t just greening—it’s being reborn. The year will not be a finish line, but a pivotal inflection point where the nascent greening of global supply chains matures into a fundamental restructuring of planetary resource flows. Driven by the brutal arithmetic of climate deadlines, resource scarcity biting deeper, and the hard-won lessons of geopolitical volatility, the post-2030 green tech supply chain transcends mere decarbonization and ethical sourcing. It evolves into an intelligent, hyper-optimized, and fundamentally circular network – a living, responsive metabolic system for the clean economy, demanding unprecedented levels of collaboration, technological audacity, and systemic thinking to power humanity’s survival and prosperity in a climate-disrupted world. The linear “mine, manufacture, discard” model is rendered obsolete, replaced by dynamic loops of resource recovery, bio-integration, and localized resilience, all orchestrated by advanced digital twins and governed by planetary boundaries as the ultimate KPI.

Picture AI-powered systems that anticipate product end-of-life the moment something is made. Solar panels, wind turbines, and EV batteries aren’t discarded anymore; they’re pre-tagged in digital twins, designed for disassembly, regeneration, and reinvention. By 2035, over 70% of lithium-ion batteries are recycled—up from a dismal 10% a decade earlier. Urban mining becomes more lucrative than traditional mining, with disused electronics yielding rare metals through advanced hydrometallurgy and AI-guided recovery.

The line between technology and biology blurs. Microbes now extract nickel and cobalt from waste streams more efficiently than smelters. Mushrooms replace plastics. Genetically engineered yeast cultures birth materials that once required petroleum. And the packaging? Grown, not manufactured.

But it’s not just technology. It’s geopolitics. Across the Global South, mineral-rich nations no longer settle for exporting ore. They’re building domestic capacity—factories, battery parks, tech clusters—to refine, manufacture, and retain value. Indonesia’s nickel empire becomes a blueprint. Governments assert their “resource sovereignty,” building alliances and demanding fairer stakes in the new clean economy. Strategic stockpiles of lithium and cobalt now sit in vaults, governed by treaties, just like oil once was.

Even the most stubborn sectors yield. Aviation and shipping—long considered hard-to-abate—shift to green hydrogen and ammonia. Heavy industry electrifies. Waste heat gets recaptured. CO₂ is pulled from the air and turned into fuels or locked into stone beneath our feet. The entire system pivots from carbon emitter to carbon sink.

Behind it all? A digital nervous system humming with intelligence. Billions of sensors monitor everything—from soil moisture in lithium mines to real-time emissions in microfactories. Quantum AI models predict disruptions, optimise routes, and pre-empt shortages. A single smart algorithm in 2040 could reroute EV battery production in seconds based on weather patterns, geopolitical risks, or emissions data. Supply chains become sentient—adaptive, predictive, even self-healing.

Yet the greatest leap isn’t just technical. It’s moral.

Regeneration becomes the metric that matters. Does this supply chain restore ecosystems? Does it pay living wages? Does it honour Indigenous stewardship over mined lands? Blockchain isn’t just tracking materials; it’s verifying justice. Contracts now include biodiversity offsets. Product labels show not just carbon footprints but community benefit scores.

Because for all our smart tech, our survival hinges on something ancient: reciprocity. Giving back more than we take.

So the green tech supply chain of tomorrow isn’t just about building a better economy—it’s about healing the one we broke. It’s about reimagining not just how we produce, but how we coexist. And that future, once distant, is arriving faster than we think.

Green supply chains have emerged as a mainstay of sustainability initiatives, vowing to shrink carbon footprints and herald a new era of sustainable manufacturing and distribution. But as corporations around the world push for greener practices, we have to ask: are these supply chains actually cutting emissions, or are they just a band-aid for a bigger issue?

Green supply chains are at the core of the promise to reduce the environmental impact while ensuring operational efficiency. More companies are adopting renewable energy integration, waste reduction, low-carbon logistics, and other measures. For example, according to the International Energy Agency (IEA), nearly 30% of global electricity generation now comes from renewable energy—with some of that transition driven by the push from businesses to go to clean energy. However, although this work is admirable, the degree of its success is critically reliant on the broader systemic changes that must take place in networked supply chains.

One of the critical stages in green supply chains is the sourcing of raw materials. Electric vehicles (EVs), for example, are powered by lithium-ion batteries that use elements like lithium, cobalt, and nickel. These materials often originate from areas with serious environmental and ethical concerns. The demand for critical minerals such as lithium, the World Bank predicts, will increase nearly 500% by 2050. Companies like Tesla and BMW have focused on blockchain and other measures to ensure ethical sourcing, something that remains a challenge when factoring in the carbon emissions associated with mining and transporting these materials. COP27’s EMU report drew on a 2022 EPA study, which estimated that the extraction and processing of these minerals can make up as much as 40% of the total lifecycle emissions produced by an EV battery.

Another urgent challenge has been the resilience of green supply chains. It highlighted weaknesses in global logistics with the COVID-19 pandemic, as 85% of renewable energy companies reported disruptions. Regionalization and diversification of suppliers can help mitigate such risks, but these strategies typically incur costs. Localized manufacturing, for instance, can eliminate some transportation emissions, but if those regional facilities are powered by fossil fuels, that could create increased energy use. A 2023 report by McKinsey noted that companies that do not fully optimize their regional supply chains “risk increasing their overall carbon footprint, despite their green intentions.”

Some of these challenges could be effectively met through circular economy practices. Zero waste and zero emissions can be replaced with the productive reuse of the process and the recycling of materials. According to the Global E-Waste Monitor 2020, only 17.4% of e-waste is recycled, and this presents a huge opportunity. Indeed, battery recycling projects, like those of Umicore, work on the principle of a closed process where reuse leads to less dependence on virgin forms of material and subsequently emissions. Scaling these practices will require significant investment and coordination on a global scale, as appropriate recycling infrastructure is lacking in many areas.

Digital transformation is yet another technology touted as a game-changer for green supply chains. AI, machine learning, and the Internet of Things (IoT) facilitate seamless tracking, forecasting, and optimization of resources. A 2023 Deloitte study discovered that there is a potential to reduce supply chain emissions by as much as 30% through digital tools. Internet of Things (IoT) sensors, for instance, can measure energy consumption and detect inefficiencies on a live basis, whereas AI analytics can plan logistics in a way that reduces fuel usage. Read more on the impact of technology on the environment and production: Experts warn of carbon glut from soaring number of computers. For example, a large server complex may consume as much energy as a small city, and the materials needed to manufacture and maintain these digital systems can be quite extensive.

To address the multiple challenges posed by green supply chains, stakeholders need to collaborate. It takes governments, corporations, and consumers working together to create standards and incentives for sustainability. The International Renewable Energy Agency (IRENA) reported that public-private partnerships have already mobilized over $2 trillion for clean energy projects since 2015. However, substantial cuts in emissions will require changes well beyond capital deployment and even regulatory structures and consumer behavior. For example, organizations like the RE100 coalition, in which companies join to aim for 100% renewable energy, show the potential for collective action, though also the importance of accountability and transparency.

Overall, although there is a great potential contribution of green supply chains to emissions reduction, the current impact is uneven. Many efforts are either make-work projects that are not integrated into operations, or they simply rely on what I describe as a greenwashing meme, where large organizations claim goals and achievements that sound good but aren’t based on an integrated approach to operations. This will require more than gradual steps toward green supply chains; it means developing integrated approaches that address the entire supply chain from material extraction through to end-of-use recycling. The journey to real sustainable supply chains is a long and winding one, and the stakes couldn’t be higher. The transition to effective, transparent, and truly green supply chains has never been more urgent as climate change speeds up. Corporates who can crack this nut will be able to achieve lower carbon footprints while building a blueprint for a sustainable future and demonstrating that economic development and protection of the environment can be mutually reinforcing.”

HKU and CATL Sign Strategic Cooperation MOU

The University of Hong Kong (HKU) and Contemporary Amperex Technology Co., Limited (CATL) signed a strategic cooperation Memorandum of Understanding (MOU) in Ningde, Fujian, on 6 June 2025 to advance comprehensive collaboration.

Leveraging Hong Kong’s international profile and its strengths as a global financial centre, along with the HKSAR Government’s commitment to carbon neutrality, the agreement focuses on three key areas:

Key Areas of Collaboration

• Formulating international zero-carbon policy standards

• Driving zero-carbon technological innovation

• Accelerating the transition to zero-carbon energy

This collaboration combines CATL’s leading expertise in zero-carbon technology with HKU’s research excellence to jointly establish an international platform for industry-academia-research cooperation, fostering global talent development and accelerating innovations to achieve carbon neutrality.

The MOU was signed by representatives from the Zero-Carbon Energy Business Unit (ZEB) of CATL and the International Centre for Climate and Nature (ICCN). The ceremony was attended by Professor Peng Gong, Vice-President and Pro-Vice-Chancellor (Academic Development) of HKU, and Mr. Yingming Wu, Chairman of the Supervisory Board and Ecological Development Committee of CATL. Also present were Professor Guochun Zhao, Academician of the Chinese Academy of Sciences, Professor Jingming Chen, Fellow of the Royal Society of Canada, along with representatives from ICCN and various CATL departments.

Key Areas of Cooperation

• Aligning international zero-carbon policies and standards

• Deepening zero-carbon technological innovation

• Accelerating the global transition to zero-carbon energy

As part of the policy and standardization efforts, both parties will work together to advance international standards for battery carbon footprint accounting.

On the innovation front, ICCN and CATL will integrate the AI-powered Earth Observation for Sustainable Development Platform (iSG) with advanced grid technologies. This will support applications in integrated power sources, smart grids, load management, energy storage systems, and virtual power plants.

For the energy transition, Hong Kong will serve as a model city, piloting scalable zero-carbon solutions across electricity grids, buildings, and transportation sectors. The collaboration will also explore innovative carbon financing mechanisms to support the development of carbon markets and strengthen alignment with international carbon standards.

This partnership represents a significant step forward in creating an ecosystem for academic and industry collaboration aimed at achieving carbon neutrality. By uniting world-class academic institutions and industry leaders, this joint initiative will meaningfully contribute to the global energy transition and carbon neutrality goals, guiding the international community toward a greener, more sustainable, zero-carbon future.

About CATL

Contemporary Amperex Technology Co., Limited (CATL) is a global leader in new energy technology innovation, dedicated to providing advanced solutions and services for new energy applications worldwide.

In June 2018, CATL was listed on the Shenzhen Stock Exchange (stock code: 300750), and in May 2025, the company was also listed on the Hong Kong Stock Exchange (stock code: 03750). In 2024, CATL ranked No. 1 globally in EV battery consumption volume for the eighth consecutive year and held the top market share in global energy storage battery shipments for four consecutive years. CATL is widely recognized by EV and energy storage partners worldwide.

In 2023, CATL announced its strategic goals of achieving carbon neutrality in its core operations by 2025 and across the entire battery supply chain by 2035, reaffirming its commitment to contributing to the global energy transition.

Public Release. This material, provided by the originating organization/author(s), may be of a point-in-time nature and has been edited for clarity, style, and length. Mirage.News does not take institutional positions or sides, and all views, positions, and conclusions expressed herein are solely those of the author(s).

“We Don’t Just Need Smart Cities, We Need Smarter Citizens”

In March 2019, standing just a few hundred miles from the North Pole as part of the 2041 Foundation expedition, environmentalist and Entrepreneur Neelima Mishra stared out across a glacial expanse, and into the heart of a global crisis. Surrounded by the surreal beauty of the Arctic, she also encountered its ugly secret: plastic bottles, cigarette butts, abandoned fishing nets and bits of trash lodged in snowdrifts. When she returned to her home city of Bhubaneswar, Odisha, the lens through which she saw the world had changed. And so, later that year, Ceiba Green Solutions was born, rooted in a simple but powerful idea — to reduce the volume of waste going to landfills while empowering citizens to take charge of their own waste footprint. The journey, however, was anything but linear.

Please tell us about your journey?

It’s important to realise that while we clean our own homes, we often end up dirtying our larger home—the planet. That realisation truly hit me during an expedition I undertook in 2019 to the Arctic, as part of the 2041 Foundation. Even in those pristine polar regions, I saw plastic bottles, cigarette butts, fishing nets—waste that had travelled far and wide. The shock of seeing human neglect in such a remote part of the planet stayed with me.

When I returned to Odisha, I couldn’t unsee the daily waste and litter around me. That’s when I knew I had to be part of the solution, not just a silent witness. We founded Ceiba Green Solutions in Bhubaneswar later that year. Of course, the pandemic hit soon after, and our plans had to be rethought. But we adapted—conducting online workshops, trainings, and continuing what work we could on the ground.

In 2021, I pursued my Master’s in the UK with a thesis on waste management. On returning, I dived back into the startup full time, determined to take our mission forwardSeeing plastic in the Arctic changed everything for me.

What is the focus of your organisation?

At Ceiba, our work revolves around four pillars—wet waste management, single-use plastic alternatives, waste-free events, and awareness-building. We provide composting services to bulk waste generators—like hotels, colleges, and government canteens—as well as individual households. Our belief is simple: if waste is segregated and composted at source, we drastically reduce what ends up in landfills.

On the dry waste side, we built the Recycle Pay app, which lets people schedule waste pickups and receive payments for recyclable materials. It’s our way of creating a micro-incentive economy around segregation.

We also launched an e-commerce platform that curates plastic-free, biodegradable products from various vendors. Sustainability should be accessible—and we’re working to make it mainstream.

Additionally, we run educational outreach programs and workshops in schools, colleges, and communities. Though our plans for zero-waste events haven’t gained traction yet, we’re hopeful for future partnerships.

What is your vision and expansion plan?

Our long-term vision is to significantly reduce landfill waste, lower GHG emissions, and make measurable progress toward the Sustainable Development Goals (SDGs). Instead of spreading ourselves thin across the country, we’re focused on deepening our impact in Odisha and Tier II cities across Eastern

India. And we’re happy to collaborate. Many organisations are doing excellent work and this is a time to work together, not just compete.

What advise would you like to give to individuals wanting to start their green business?

You don’t need to be an entrepreneur to fight climate change. You can be part of a local group, raise awareness in your neighborhood, or make sustainable lifestyle choices. That alone makes a difference.

If you do want to start a green venture, take time to understand your sector deeply. Get a good mentor and it should be someone who can challenge and guide you. Join incubator programs or networks that help refine your ideas and strategy. Passion is vital, but without a business model, it’s not sustainable.

Any lessons learnt during your journey that you would like to share with us?

Plenty. But one that stands out is this: passion alone won’t carry you through. You need to back it up with a viable business strategy. It’s easy to get caught

up in the idealism of the green movement, but the ground reality involves numbers, scale, and execution.

Also, staying honest in a space like this is vital. There’s a lot of greenwashing out there, and it erodes trust. If you’re working for the planet, your integrity must be non-negotiable, towards both the environment and the people you serve.

How has being a green entrepreneur impacted your personal values?

Actually, it was the other way around. My personal values shaped the business. I’ve always loved the outdoors. That love became the anchor for Ceiba. Every

time we reach a new person, we grow that love. Every compost bin installed, every plastic-free product sold, every school session held and that is how we

expand our circle of impact.

Do you think the time for green businesses is here?

Without a doubt. We are already witnessing a tectonic shift in how we live and consume. I believe five areas will define the new green economy—how we manufacture, how we eat, how we travel, how we consume energy, and how we live.

But this transformation isn’t just the responsibility of green startups. Corporates, tech firms, and even local governments must integrate sustainability into their ecosystems. We need systemic change. And that’s where it all starts with you and me. With every choice we make.

QUESTION — Can you please introduce yourself and your role in the green business? Tell us about your journey and your motivations.

I’m an engineer, specializing in electronics, software, and firmware. My primary focus is designing and coding embedded systems, those small control devices that are ubiquitous in our world. This interest stemmed from helping my grandfather, a TV repairman, in his shop as a child. His mentorship instilled in me the belief that technology was accessible to anyone willing to learn. Thus, I delved into books and self-learning, bypassing formal education initially.

Despite not attending college at first, I immersed myself in technology. I was captivated by early computers and machines, eventually working for companies that supplied components for these systems. My career progressed from technical sales to management roles, driven by my passion for technology. Even without a formal degree, I honed my skills through continuous learning and hands-on projects.

I eventually pursued education part-time, earning a two-year degree followed by a bachelor’s degree later in life. However, I consider myself largely self-taught, constantly seeking knowledge from experts and experimenting with new ideas. My journey underscores the importance of sharing knowledge and leveraging technology for societal benefit.

Driven by a desire to make a meaningful impact, I co-founded a company focused on designing beneficial solutions. This transition was prompted by a disconnect between my role as a director of engineering and my passion for hands-on projects. My friend and I shared this sentiment, leading us to start our venture.

Reflecting on my journey, I attribute my interest in exploring different cultures and environments to childhood experiences. Traveling, whether to remote beaches in Mexico or business trips abroad, has broadened my perspective and fueled my curiosity. I’ve always been drawn to unfamiliar places, eager to learn from diverse communities and experiences.

In summary, my career trajectory underscores the importance of curiosity, a desire to make a positive impact, and a willingness to embrace new challenges and environments. These qualities have shaped my journey as a technologist and social entrepreneur, guiding me towards endeavors that blend innovation with social responsibility.

QUESTION – What are some of the biggest lessons that have shaped you as a human?

Exploring unusual places offers insights that are often overlooked in urban settings. These environments can teach valuable lessons about longevity, health, and connection to nature. For instance, documentaries showcasing lifestyles in Puerto Rico and other South American regions highlight healthier living habits, resulting in a higher number of centenarians. These experiences provide a different perspective on happiness, health, family dynamics, and the concept of abundance. Overall, such perspectives enrich our understanding of humanity and shape us in profound ways.

QUESTION — What motivated you in the field of becoming a green entrepreneur? Were there any turning points or specific incidents?

Working alongside my friend Kurt Coleman at Microchip, a microcontroller manufacturer, I got involved in his side project called Light Up the World. It was an off-the-books endeavor, occupying our weekends and spare time. This experience was more fulfilling to me than any meeting, promotion, or stock grant could ever be. It sparked the realization that I could use my skills for meaningful community impact. Prior to this, I had volunteered in various capacities but hadn’t found a way to align my work skills with community needs.

Designing products for underserved communities opened my eyes to the challenges they face—unsafe water, polluted air, lack of electricity, and inadequate government services. Despite the sacrifices involved, the work was rewarding in itself. Collaborating with Kurt on projects like UV water purification was fulfilling, but I recognize that our success was part of a larger team effort. Our work has contributed to improving hygiene and lighting in villages, and other organizations have benefited from our expertise. It’s satisfying to see the ripple effect of our contributions, knowing that we’ve played a part in positive change.

QUESTION — Can you highlight some innovative or unique aspects of your sustainable business model?

Learning from failure is crucial in any endeavour. There are various pathways to success, but two common approaches are organic growth and immediate skill application. The former involves cultivating a seed over time, which is sustainable but less likely to succeed quickly. Conversely, the latter requires identifying and immediately utilizing a skill, which may yield quicker results but can be challenging to navigate.

People often enter this space from diverse backgrounds. Some start from grassroots efforts, like individuals in Guatemala developing water purification solutions over years. Others involve collaborating with locals to address specific needs, such as improving stove efficiency to reduce indoor air pollution.

Successful projects often prioritize tangible solutions over complex technologies. For example, in Guatemala, educating communities about water cleanliness proved more impactful than introducing UV purification systems. Similarly, addressing indoor air pollution involved showing villagers the immediate health risks and providing simple, effective stove designs.

Ultimately, the best projects focus on localized, sustainable solutions that address immediate needs without leaving behind complex technology or products.

QUESTION — What were the challenges you encountered and how did you overcome those?

Several challenges have left a lasting impact, notably the 2008 economic downturn. Our projects in various countries, like India, Mexico, and Uganda, faced setbacks as partners struggled with layoffs and budget cuts.

We pursued a model of partnering with established Western companies to expand into new markets. For example, we collaborated with BioLite to distribute clean-burning stoves in Africa and India. Similarly, we worked with companies like CamelBak and Cascade Design on water purifiers and electric chlorinators.

However, relying too heavily on these partnerships posed risks. While joining forces with larger companies offered resources, it also made us vulnerable to their decisions. Maintaining a degree of self-sufficiency is crucial to mitigate such risks.

Partnering with industry giants like Unilever can yield significant benefits, but it also carries the risk of dependence. Finding a balance between leveraging resources and maintaining autonomy is key to navigating such collaborations successfully.

QUESTION — How do you measure the environmental impact of your business? (Will be adding data to this once Dan provides it)

There are instances when quantifying impact is feasible, especially with commodities like solar home systems, where daily power generation can be measured. Similarly, interventions in areas like Guatemala, targeting stove usage or water handling, allow us to track indicators such as the reduction in dysentery cases or improved school attendance.

While these measurements provide indicators rather than definitive proof, sometimes you have to rely on intuition and observation. You can sense the positive changes, like increased happiness among people, even if it’s not quantifiable. Moreover, the infrastructure itself often yields benefits beyond the immediate outcomes, such as job creation and skill development.

By teaching individuals skills like water analysis or stove maintenance, you leave behind a legacy of technological empowerment, enriching their lives in ways that extend beyond the initial intervention.

QUESTION — How do you envision the future of sustainable entrepreneurship worldover?

Progress often takes unexpected paths. Sometimes it’s not about technological breakthroughs, but rather the acceptance of existing technology. For instance, solar panels and LEDs have been around for decades, but innovations like white LEDs have made significant differences. Moreover, new distribution networks and finance models, such as pay-as-you-go and micro-lending, have enabled previously non-existent business models.

Looking ahead, I’m particularly intrigued by the potential of artificial intelligence (AI). AI could revolutionize everyday life, serving as an assistant teacher, aiding those with disabilities, and providing invaluable support in various tasks. Despite often being associated with corporate exploitation, technology has immense potential for good, from agricultural advancements to personalized assistance.

While I’m not an expert in this field, I’m actively learning and exploring opportunities. Currently, I’m working for a company where I see the potential for integrating AI into their products. This role allows me to gain valuable skills while keeping an eye on my long-term goal of contributing to meaningful technological advancements.

Overall, I’m optimistic about the future and eager to continue my journey in this direction, balancing my current responsibilities with my aspirations for making a positive impact through technology.

QUESTION — So are there any lessons you’ve learned in this journey that you wish someone had shared with you earlier?

The allure of understanding how things function has led me to share this fascination with numerous individuals, fostering an appreciation for technology, electronics, firmware, and the intricate workings of the world around us. From the mysteries of the human brain to the complexities of ecosystems, there’s an endless array of captivating phenomena to explore.

Curiosity, in itself, is a rewarding pursuit. Whether delving into the intricacies of biology or immersing oneself in the art of music, the journey of discovery enriches our lives. While I understand the appeal of simple pleasures like video games, I advocate for embracing curiosity and actively seeking to expand our understanding of the world.

Being overzealous in my pursuit of inspiration, I believe in seizing each day to its fullest potential, embracing learning and fascination as integral parts of life’s journey.

Copyright © 2026 Green Trendsetters. Terms of use. Privacy policy.